LESS BRAKES Introduces Innovative Brake Pads

LESS BRAKES has developed innovative pads capable of adapting to the needs of riders and to different forms of braking, improving your feeling on the brake lever without the need to change your brake brand or model.

Thanks to their exhaustive research and strong commitment to high quality materials, the company has developed brake pads that will allow you to adapt your braking sensation to your riding style, from more direct to more progressive.

From the beginning, their main goal has been to elaborate top quality products, that’s why they have been working hard, researching and developing the best components to achieve their final products. Their Resins, Kevlar and Copper fibers are provided by the best manufacturers in the world, like Hexion, Momentive or Dupont, who are based in countries like USA, Germany and Japan.

This allows LESS BRAKES to offer a wide product portfolio, including brake pads compatible with the main brands in the industry, such as Shimano, Sram, Hope, Magura, Formula, Trp, Trick Stuff, Avid or Tektro.

There is a main reason why their brake pads are unique in the industry: the development of their technology is based on the rider’s feeling of braking and how they can modulate it. This means that, with the same brand and model of brakes, riders can vary and achieve different types of braking changing only the type of pads.

In order to choose the right brake pad compound, it is of vital importance to be fully aware of the performance of each of the compounds, to determine the discipline in which it will be used and to know the basic parameters for measuring its real behaviour and performance.

The rider must be aware that there is no ideal and general brake pad for use in all conditions. Each compound has been developed to offer the best possible functions in each of the specific fields in which cycling is currently practiced.

There are very clear differences in the performance of each compound. Each has a specific function, with its pros and cons, so selection criteria must not simply be focused on the functions that it offers, but also on other important aspects, such as wear and the convenience of use of the brakes.

MAIN PARAMETERS TO DETERMINE BRAKE PADS PERFORMANCE

To make a well-advised decision on the brake pad compound required, it is vital to base the decision on a series of parameters that characterise braking capacity. Broadly speaking, this can be summarised in two main aspects: efficiency and wear.

–Efficiency is measured through the friction coefficient offered by the compound (braking power), the characteristics of this friction (progressiveness) and its stability depending on important factors such as temperature and humidity.

-Wear is determined according to the amount of friction material consumed when braking, both of the brake pads and of the brake discs.

WHAT ARE THE MODELS AND COMPOUNDS OF LESS BRAKES?

LESS BRAKES has developed 3 types of compounds, adapted to different requirements and circumstances.

1. BALANCED/SEMI-METALLIC

XCO / XCM / Road / E-Bike / Enduro / DH

Neutrality and linearity at once and an unbeatable price/power ratio.

The main objective of this compound is to offer the possibility of buying high-performance brake pads at a very competitive price. LESS BRAKE has combined all the advantages of its organic base compound with a touch of abrasiveness, by using metallic components in the phenolic material.

Organic base guarantees reactive and stable braking without a long run-in period, while the metallic components increase the friction coefficient offered by the organic base, significantly improving wear resistance.

In short, this gives reactive and powerful brake pads at low/medium temperatures, offering low noise, a short run-in period and good wear resistance.

PERFORMANCE:

– Direct and stable braking.

– Barely noisy.

– Don ́t need a big break-in phase.

– Very good price/performance ratio.

2. POWERFUL/ SINTERED

E-Bike / Enduro / DH

Get a direct and sudden reaction with maximum power and reactivity even in wet conditions.

Based once again on the aspect of modulation in the braking system, the sintered compound offers a totally different performance to the ceramic compound. This will allow riders to obtain a totally different reaction with the same model of brake, thus offering a high level of customisation, even the type of braking desired in both the front and back brakes independently.

Powerful brake pad offers a super direct feel on the brake lever and generates huge braking power. This is, by far, the compound with the greatest friction coefficient offered by the brand and its functions remain intact even in wet and muddy conditions. They are prone to generating noise in this type of conditions, so it is advisable for riders to properly evaluate their criteria before opting for this specific compound.

They offer a high level of wear resistance due to their metallic powder composition. This gives us long-lasting brake pads, although it does increase wear on the brake disc.

Sintered pads offer maximum braking power and a highly reactive feel on the brake lever. They generate an extremely high friction coefficient in any weather, meaning that the brake feel will be the same in dry or humid conditions. It is your best choice if you are looking for a direct and reactive feel on your brakes.

PERFORMANCE:

– Super direct and reactive fell on the lever.

– Maximum braking power.

– Good performance in water and mud.

– Great durability.

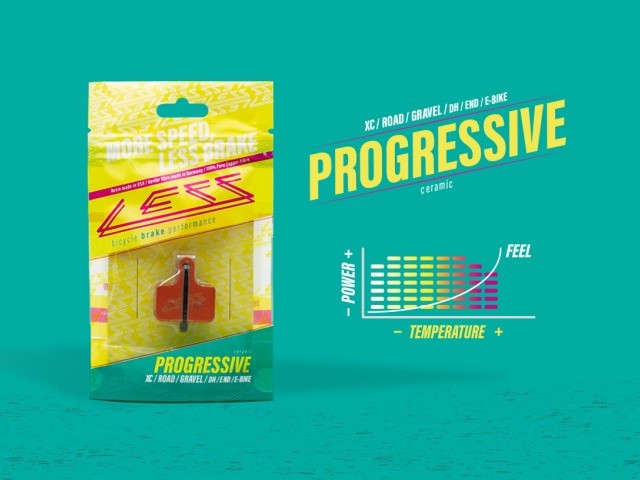

3. PROGRESSIVE COMPOUND / CERAMIC

XCO / XCM / Road / E-Bike / Enduro / DH

Looking for progression and smoothness? Modular braking in long-lasting and ultra-quiet brake pads.

Brake modulation is a key aspect when choosing a brake brand or model for advanced users in the world of cycling. With this compound, the goal is to give riders the possibility of altering the feel and reactivity of both the front and rear brakes, offering very specific braking characteristics that can be adapted 100% to their needs.

Progressive model is a fully ceramic compound, which is totally metal free and offers a progressive and modular feel on the brake lever, maintaining a high and stable friction coefficient in almost the entire temperature range of use, being much more stable than the semi-metallic compound.

Another of the main qualities provided by the ceramic compound is the low noise level that it generates, but not only that, it is also the compound with the highest wear resistance, making it the quietest and most long-lasting range of brake pads currently offered by the brand.

This particular compound requires an appropriate run-in period to achieve perfect adaptation to the brake disc, being a basic requirement to ensure its best possible functions.

Ceramic compound guarantees highly progressive and stable braking over a wide operating temperature range. They are also extremely quiet and offer a high level of wear resistance.

PERFORMANCE:

– Soft and progressive feel on the brake lever.

– Stable and controlled braking.

– Very quiet (mute effect).

– Great resistance to wear.

To sum up, analyse your technical needs and remember to choose the pads that, apart from giving you the best performance, are fully adapted to your braking preferences and other important factors like weather and surface conditions or preferred compounds.

LESS BRAKES pads offer riders the possibility of choosing the best option for their needs and the security of having an innovative and top quality product that is unique in the market and fully adaptable to all your riding requirements.

You can find more technical information at: http://www.lessbrakes.com